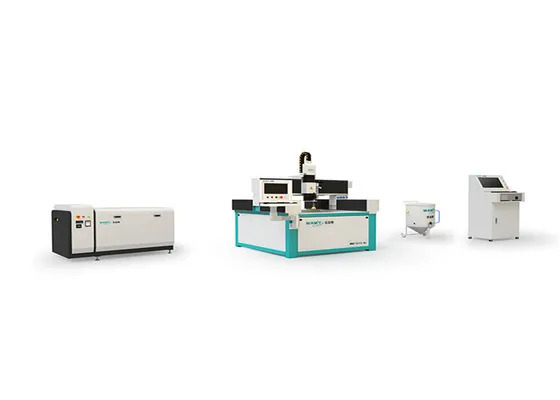

The WMT 500 Series is designed for cutting large and ultra-thick materials. Its reinforced water tank and heavy-duty platform support up to 2 tons per square meter, with a 120 mm grid structure that ensures high flatness and extended durability.

To simplify abrasive removal, the platform is engineered to withstand the weight of a small excavator, allowing direct removal of waste abrasive, which saves significant maintenance time. The motion system features high-precision HIWIN linear guides and YYC gear racks from Taiwan, delivering up to 50 m/min cutting speed, excellent accuracy, long lifespan, and high production efficiency.

1. Gantry machine design, high temperature forging, durable.

2. Ultra-high pressure cutting head, can be cut with pure water and abrasive.

3. With 3-axis and 5-axis tool heads, vertical and non-vertical cutting can be performed, and the maximum cutting Angle is 60 degrees.

4. Japan HERG automatic lubrication system;

5. Internal components selected from Schneider international brand, reliable quality, durable;

6.Taiwan HIWIN linear guides, and Taiwan TBI ball screws.

7. WEIHONG waterjet CNC cutting system is adopted.

8. Z-axis fully closed structure, no water and sand, higher cutting accuracy;

9. The model can be customized, according to the need to develop and design exclusive styles.

10. The first generation of self-designed ultra-high pressure servo direct drive pump, more energy saving, ecological environmental protection, lightweight; Ultra-high pressure booster pumps are easier to operate and maintain.

11. Intimate after-sales: equipment maintenance and repair, support online video technical support, installation, commissioning and training and free spare parts support.

Send Inquiry

Send Inquiry Call Me Free

Call Me Free